Lubricant Oil

Lubricant Oil

Typically, industrial lubricants contain 70-90% base oils and the rest is additives. Base oils impart primary vital properties of the lubricant such as viscosity, viscosity stability, thermal stability, solvency, low temperature flow and volatility, oxidation stability. The primary function of Lubricant additives is to improve the properties of the base stock under different operating conditions and the high-performance requirements of any machinery. Lubricant additives can be categorized into various kinds based on their general roles of performance improvement and service life extension.

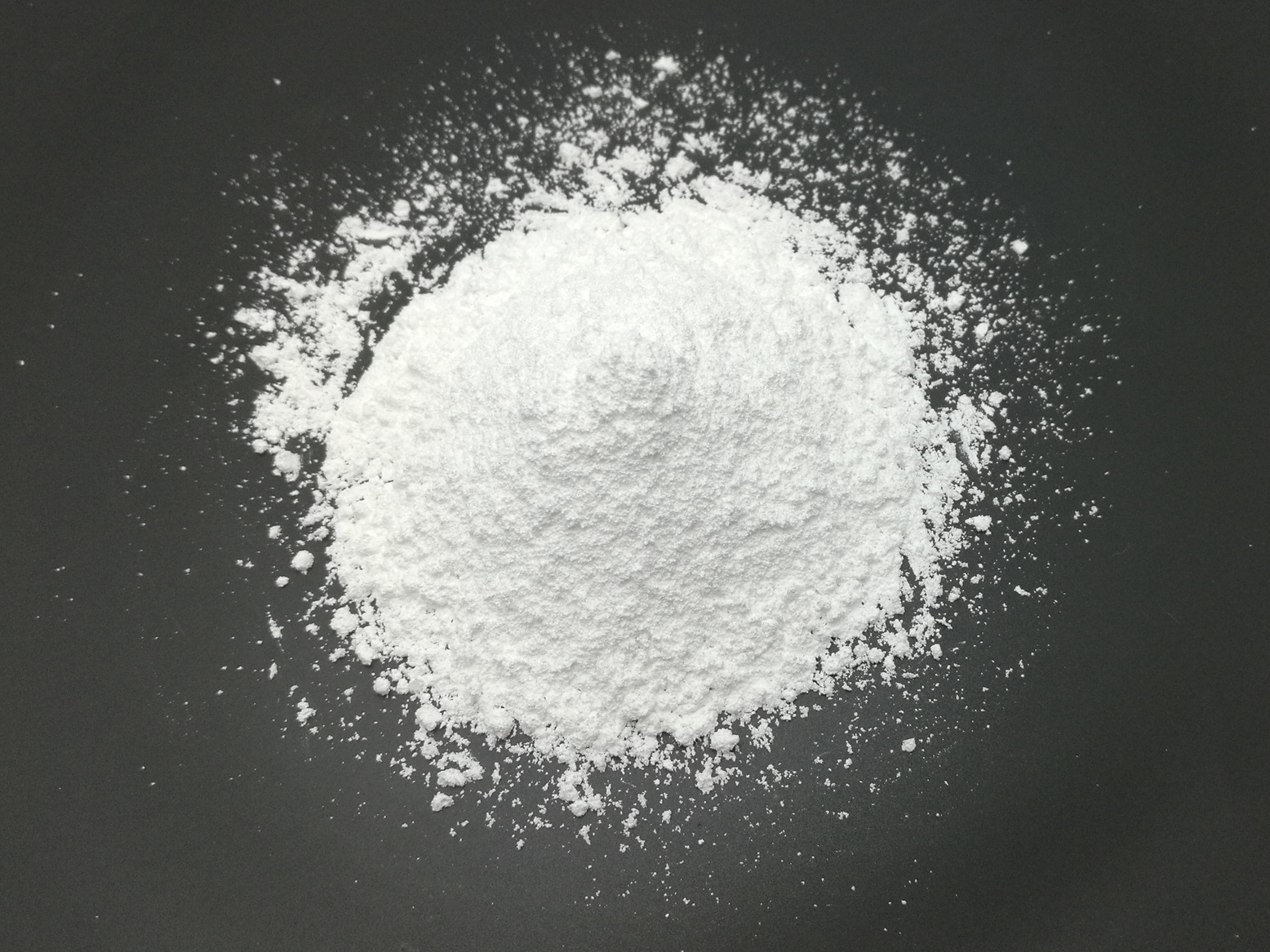

Magnesium Oxide is typically used for the production of Magnesium Sulfonate which is one of the commonly used ingredients in lubricant additives – detergents. The final products of combustion and lubricant decomposition (due to contamination, heat, age or other causes) include organic and inorganic acids, aldehydes, ketones, and other oxygenated materials. The acids have the propensity to attack metal surfaces and cause corrosive wear. The byproducts can also form sludge and varnish, which may lead to clogging of filters, orifices and ports; increased heat; and inadequate lubrication. Detergents, especially basic detergents, contain reserve base that will neutralize the acids to form salts and dissolve degradation byproducts to help prevent the formation of sludge and varnish.

Lubricant additives have a complex and special production process. IMC has developed two particular high-grade magnesium oxide products to meet customer needs.

Recommended Products