Hydrometallurgy

Hydrometallurgy

Hydrometallurgy refers to the extraction of metals and production of inorganic substances from minerals through aqueous solutions. Although the entire amount of iron, lead, tin, and antimony and major production of copper and nickel come from the pyrometallurgical route, hydrometallurgy plays an important role in the extraction of reactive and rare metals and some common metals (e.g., aluminum, uranium, thorium, zinc, nickel, tungsten, and molybdenum).

In hydrometallurgy, there are two major steps for obtaining the metal value. The first one, known as leaching or lixiviation is carried out with the objective of bringing the metal into aqueous solution. In the second step, the metal is recovered from the leach liquor by cementation or precipitation by controlling the operating conditions/variables.

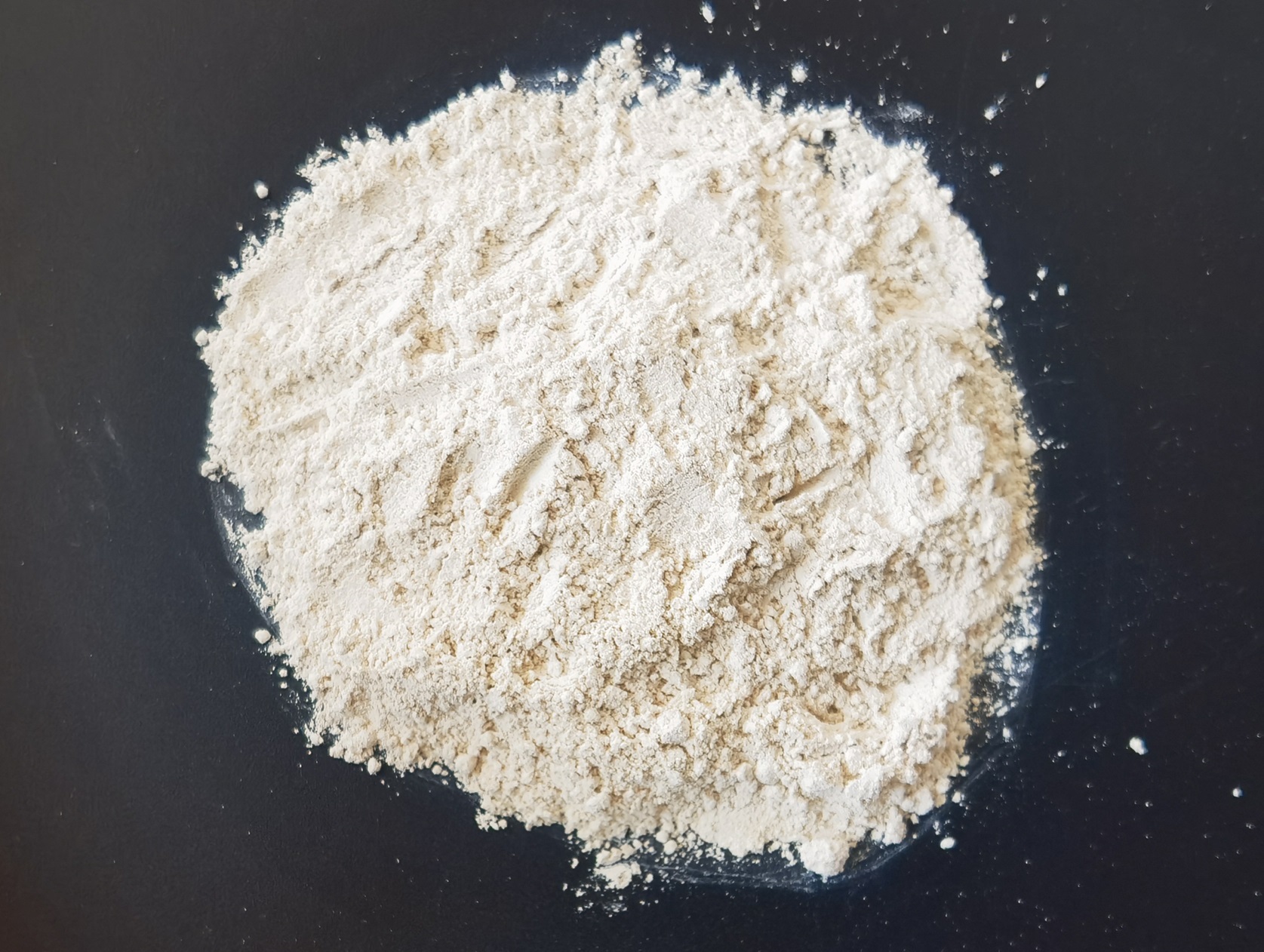

Magnesium Oxide (MgO) is one of the often-used alkali reagents for precipitation step. Effective chemical precipitation can be achieved with MgO due to its excellent pH control. In order to maximize the recovery of valuable metals such as uranium, cobalt, copper and nickel from an acid leach solution, a high purity MgO with high reactivity is recommended. For example, in uranium extraction, magnesium diuranate is precipitated by adding MgO to the uranyl sulfate solution obtained after sulfuric acid digestion.

Compared NaOH, Na2CO3 and CaO, MgO has a pH buffering ability to realize much better pH control, resulting in higher metal selectivity. MgO is environmentally friendly, non-toxic, non-corrosive, non-hazardous and safe to handle.

IMC has developed two magnesia products with suitable purity and reactivity for hydrometallurgy, providing excellent metal recovery and improved MgO utilization.

Recommended Products

Cryptocrystalline Magnesia can be used in the hydrometallurgical industry to provide good metal recovery rates; and as an additive in the production of friction materials to improve the thermal stability of materials and resist high friction temperatures.