Magnesium Oxide Board

Magnesium Oxide Board

Evolving construction methods and an increasing demand for materials with enhanced fire resistance have created a demand for novel materials within the construction industry. Over the past two decades, Magnesium Oxide (MgO) boards have become more widely used as a solution to the needs of modern construction.

MgO boards are large-sized structural boards, typically white. They are usually produced by combining MgO with chloride/sulfate, perlite, non-woven fabric, glass fabric, wood dust, water. In fact, there will be some different MgO board recipes, depending on the use environment and target properties.

MgO boards can be applied as wall sheathing, trim, fascia, and siding on the exterior of houses. Inside homes, MgO boards serve as tile backers, wall panels, wall linings, firewalls, partitions, shaft liners, soffits, sub-floorings, ceilings, drop ceiling tile, and wherever a building needs to be protected against fire, rotting or molds.

Thanks to the properties of raw materials and modern production process, MgO boards are safe and environmentally friendly products, with important advantages that are fire-proof, heat-proof, elastic, strong, frost-resistant, water-proof, sound-proof, healthy, non-toxic, anti-allergic, and resistant to molds and rodents. Ongoing researches show that MgO boards have certain ability of consuming CO2 from the air throughout their life cycle due to MgO properties, thereby continuously improving the quality of the indoor environment.

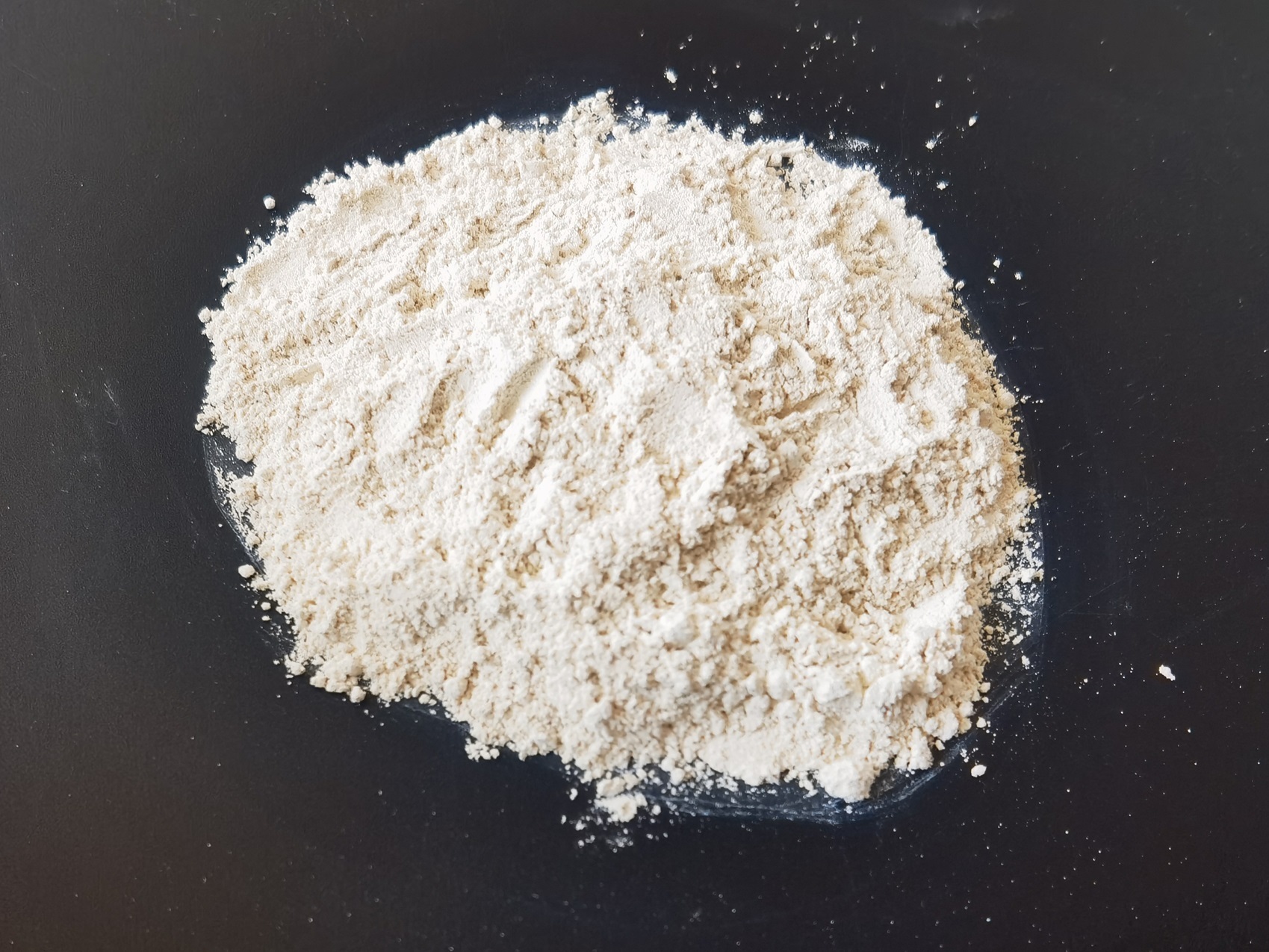

IMC supplies superior magnesium oxide products as raw material for the production of high-quality MgO boards.

Recommended Products