Drilling Fluids & Cements

Drilling Fluids & Cements

Oil extraction is an extremely complex process that requires using about hundreds of chemicals to collaborate to complete each step of the work, such as drilling, cementing and testing, well completion, fracking, production and fracking fluid recycling, well abandonment and land restoration.

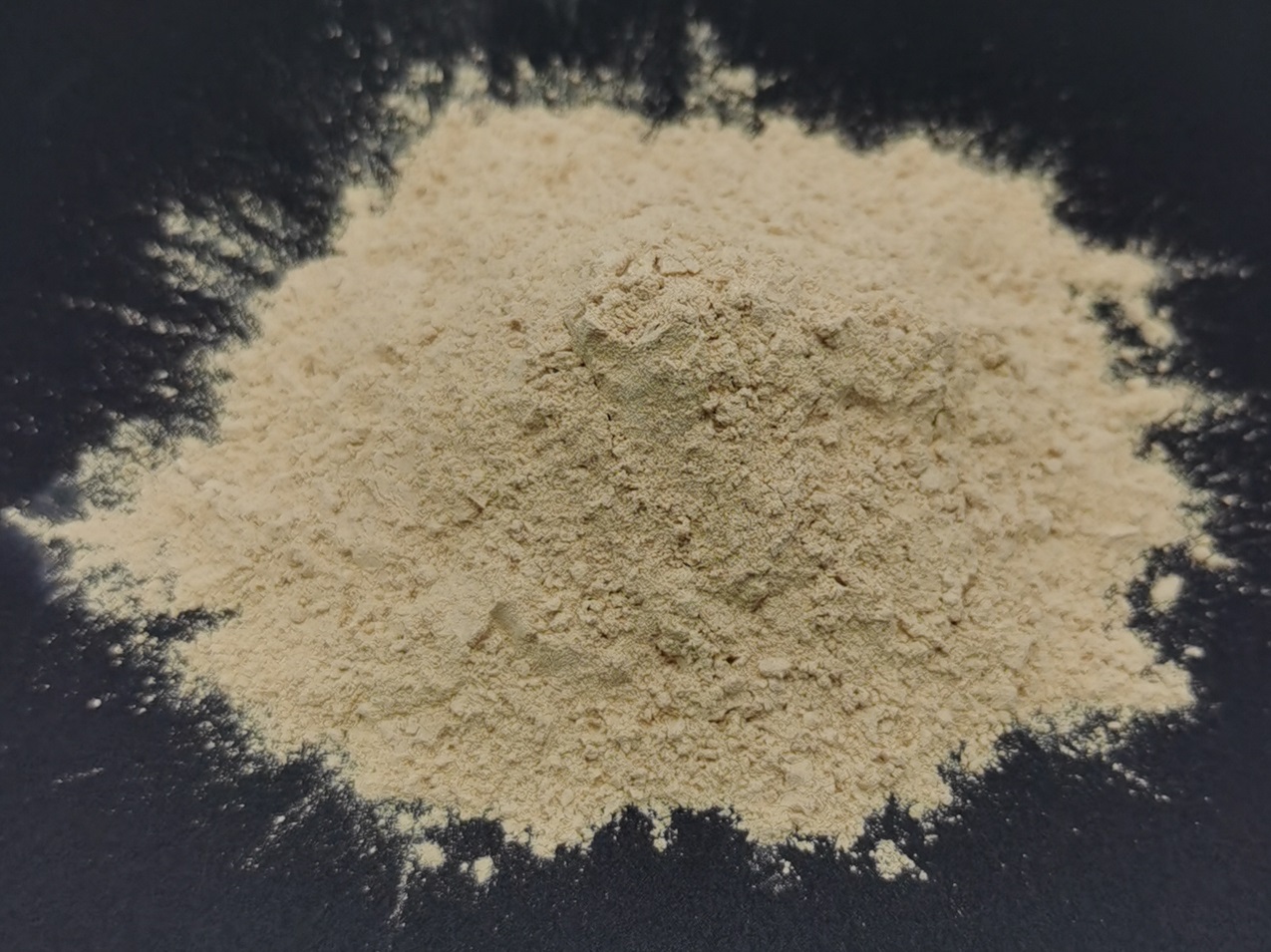

Researches and practices show that magnesium oxide (MgO), as one of many ingredients in some additives, can be involved in generating some important functions.

Drilling Mud

• Biodegradable Composition. Some oil-based drilling fluids are biodegradable. MgO, as a soap-making agent, makes up about 1-3% of the Biodegradable Drilling Fluid.

• Thickeners. MgO is useful for activation.

Fluid Loss Additives

• Bridging Agents for Fluid Loss Control.

• Additives to Reduce Fluid Loss.

Filter Cake Removal

• Bridging agents. MgO together with some other oxides can be used in combination with hydroxyethyl cellulose as fluid loss agents, and xanthan as suspension aid for solid particle bridging agents.

• Self-destructing Filter Cake.

Cement Additives

• Low-temperature Cement. MgO is used in MgO-based accelerators.

• Magnesian Cement for establishing the desired seal and being dissolved.

• Foam Cement.

• Expansion Additives for combating cement shrinkage.

Fracturing Fluids

• Ceramic Particles for use as a well proppant.

• pH-Control additives. Increase the stability of fluid (e.g., for elevated temperature applications)

Waste Disposal

• Discharge in Cement. MgO is used as a binder for stabilization and solidification.

IMC provides MgO products used in oil field with corresponding specifications based on customer requirements.

Recommended Products