Brucite Grade I-IV

- Main Uses & Advantages

- Packaging & Storage

- 概要位置

- 顶部大图

- 蓝色模块数据小图

-

- Commodity name: Brucite Grade I-IV

- Mgo Content:: 1

- typ:: 1

- Appearance: : 1

- Powder/Granular/Pellet Grain Size: 1

- Other indicators:: 1

Brucite is decomposed into magnesium oxide and water at 330℃, making it an excellent safe and environmentally friendly Flame-Retardant filler with characteristics of low smoke, no toxicity, negligible corrosion and cost efficiency.

Mg(OH)2, the main ingredient in brucite, provides a moderate and sustained alkalinity for precipitation of heavy metals, neutralization of acidic liquids and gases, and stable pH control, making it very useful in the industries of Wastewater Treatment and Flue Gas Treatment.

-

Big PP bag with or without bottom spout, with or without PE liner.

Store product in a dry area, remaining sealed.

Shelf life is 24 months under good storage condition.

-

Brucite is a natural magnesium hydroxide (Mg(OH)2) particularly sought after for its flame-retardant properties, as a raw mineral for the production of caustic or dead-burned magnesia, a variety of other industrial mineral uses, and as a high-grade ore mineral for the production of magnesium metal. Brucite has an advantage over magnesium carbonates, such as magnesite and dolomite, because it does not contain CO2 in its crystal structure. Consequently, there is no CO2 released during the calcining or other processing of this mineral except from fuel combustion. This advantage is becoming even more important as CO2 is considered the main greenhouse gas contributing to global warming.

IMC offers Brucite Grade I-IV mined from high-quality deposits according to customer needs and industry applications.

-

-

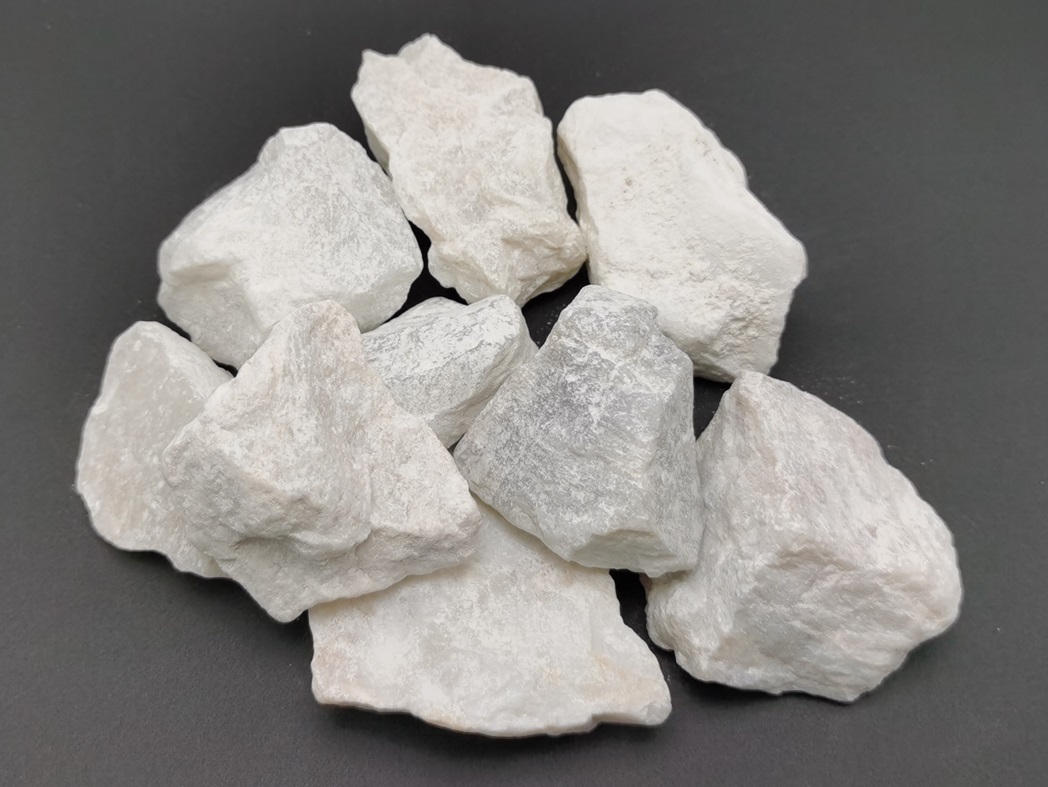

Main Properties Mgo Content 58%/60%/62%/64% Mg(OH)2 Content 84.1%/87%/89.9%/92.8% Appearance Greenish and White Rocks Grain Size Lumps/Pellets/Powder Fe2O3 0.15% max.

- Main Uses & Advantages

- Packaging & Storage

- 概要位置

- 顶部大图

- 蓝色模块数据小图

-

- Commodity name: Brucite Grade I-IV

- Mgo Content:: 1

- typ:: 1

- Appearance: : 1

- Powder/Granular/Pellet Grain Size: 1

- Other indicators:: 1

Brucite is decomposed into magnesium oxide and water at 330℃, making it an excellent safe and environmentally friendly Flame-Retardant filler with characteristics of low smoke, no toxicity, negligible corrosion and cost efficiency.

Mg(OH)2, the main ingredient in brucite, provides a moderate and sustained alkalinity for precipitation of heavy metals, neutralization of acidic liquids and gases, and stable pH control, making it very useful in the industries of Wastewater Treatment and Flue Gas Treatment.

-

Big PP bag with or without bottom spout, with or without PE liner.

Store product in a dry area, remaining sealed.

Shelf life is 24 months under good storage condition.

-

Brucite is a natural magnesium hydroxide (Mg(OH)2) particularly sought after for its flame-retardant properties, as a raw mineral for the production of caustic or dead-burned magnesia, a variety of other industrial mineral uses, and as a high-grade ore mineral for the production of magnesium metal. Brucite has an advantage over magnesium carbonates, such as magnesite and dolomite, because it does not contain CO2 in its crystal structure. Consequently, there is no CO2 released during the calcining or other processing of this mineral except from fuel combustion. This advantage is becoming even more important as CO2 is considered the main greenhouse gas contributing to global warming.

IMC offers Brucite Grade I-IV mined from high-quality deposits according to customer needs and industry applications.

-

-

Main Properties Mgo Content 58%/60%/62%/64% Mg(OH)2 Content 84.1%/87%/89.9%/92.8% Appearance Greenish and White Rocks Grain Size Lumps/Pellets/Powder Fe2O3 0.15% max.

| Main Properties | ||

| Mgo Content | 58%/60%/62%/64% | |

| Mg(OH)2 Content | 84.1%/87%/89.9%/92.8% | |

| Appearance | Greenish and White Rocks | |

| Grain Size | Lumps/Pellets/Powder | |

| Fe2O3 | 0.15% max. |

Recommended Applications

Compared with halogen-based and phosphate-based flame retardants, magnesium hydroxide (MDH) has excellent flame-retardant performance with characteristics of low smoke, no toxicity, negligible corrosion and cost efficiency.

Magnesium Hydroxide can be used as safe, eco-friendly flame-retardant filler with high fire performance class in ACPs.

There are two major roles of Magnesium Hydroxide in water treatment: 1) to provide alkalinity to realize pH control; 2) to precipitate dissolved heavy metals and neutralize acidic wastewater.

Magnesium Hydroxide is an efficient alkaline sorbent during flue gas treatment process to reduce the amount of pollutants emitted from the burning of fossil fuels at an industrial facility, a power plant, or another source.