General DBM 90%-98%

- Main Uses & Advantages

- Packaging & Storage

- 概要位置

- 顶部大图

- 蓝色模块数据小图

-

- Commodity name: General DBM 90%-98%

- Mgo Content:: 1

- typ:: 1

- Appearance: : 1

- Powder/Granular/Pellet Grain Size: 1

- Other indicators:: 1

The main application of DBM is the refractory industry, such as steel and glass industries. IMC offers high quality DBM products as raw material for production of Refractory Mass.

InnoMag®D - Dead Burnt Magnesia Typical Chemical Value (Standard Grades) InnoMag D-Series MgO % CaO % SiO2 % Fe2O3 % Al2O3 % LOI % Grain size InnoMag D90 90 min 3.0 max 5.0 max 1.7 max 1.7 max 0.5 max Customized InnoMag D92 92 min 3.0 max 5.0 max 1.7 max 1.7 max 0.5 max InnoMag D94 94 min 3.0 max 5.0 max 1.7 max 1.0 max 0.6 max InnoMag D97 97 min 3.0 max 5.0 max 1.0 max 1.0 max 0.5 max InnoMag D975 97.5 min 3.0 max 5.0 max 1.0 max 1.0 max 0.5 max -

20kg PP/PE bag.

25kg PP/PE bag.

50kg PP/PE bag.

Big PP bag with or without bottom spout, with or without PE liner.

Store product in a dry area, remaining sealed.

Shelf life is 24 months under good storage condition. -

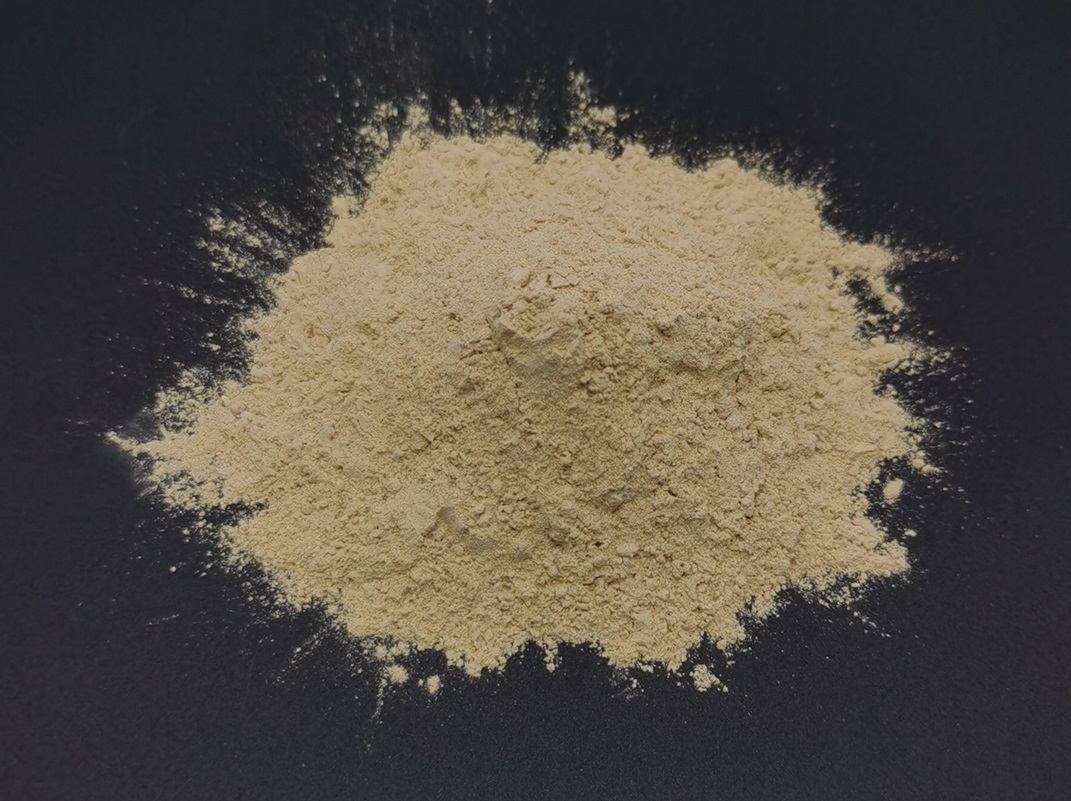

Dead Burnt Magnesia (DBM), also called sinter magnesia is produced by firing with a high temperature at around 1500-2000 °C. It has a cubic crystal system, and a bulk-density in the range of 3.00-3.45 g/cm3. The size of the crystals ranges from 50-200 pm.

-

-

Main Properties MgO Content (typical) 90%-97.5%

- Main Uses & Advantages

- Packaging & Storage

- 概要位置

- 顶部大图

- 蓝色模块数据小图

-

- Commodity name: General DBM 90%-98%

- Mgo Content:: 1

- typ:: 1

- Appearance: : 1

- Powder/Granular/Pellet Grain Size: 1

- Other indicators:: 1

The main application of DBM is the refractory industry, such as steel and glass industries. IMC offers high quality DBM products as raw material for production of Refractory Mass.

InnoMag®D - Dead Burnt Magnesia Typical Chemical Value (Standard Grades) InnoMag D-Series MgO % CaO % SiO2 % Fe2O3 % Al2O3 % LOI % Grain size InnoMag D90 90 min 3.0 max 5.0 max 1.7 max 1.7 max 0.5 max Customized InnoMag D92 92 min 3.0 max 5.0 max 1.7 max 1.7 max 0.5 max InnoMag D94 94 min 3.0 max 5.0 max 1.7 max 1.0 max 0.6 max InnoMag D97 97 min 3.0 max 5.0 max 1.0 max 1.0 max 0.5 max InnoMag D975 97.5 min 3.0 max 5.0 max 1.0 max 1.0 max 0.5 max -

20kg PP/PE bag.

25kg PP/PE bag.

50kg PP/PE bag.

Big PP bag with or without bottom spout, with or without PE liner.

Store product in a dry area, remaining sealed.

Shelf life is 24 months under good storage condition. -

Dead Burnt Magnesia (DBM), also called sinter magnesia is produced by firing with a high temperature at around 1500-2000 °C. It has a cubic crystal system, and a bulk-density in the range of 3.00-3.45 g/cm3. The size of the crystals ranges from 50-200 pm.

-

-

Main Properties MgO Content (typical) 90%-97.5%

| Main Properties | ||

| MgO Content (typical) | 90%-97.5% |

Recommended Applications

MgO-based basic ramming and gunning mass are used for the repair of steelmaking electric arc furnaces, induction furnaces, steel converters (BOF), ladles, hot metal mixers, RH degasser, etc. MgO-based basic spray mass and dry vibrating masses are used widely for tundish hot face lining.