General CCM 60%-98%

- Main Uses & Advantages

- Packaging & Storage

- 概要位置

- 顶部大图

- 蓝色模块数据小图

-

- Commodity name: General CCM 60%-98%

- Mgo Content:: 1

- typ:: 1

- Appearance: : 1

- Powder/Granular/Pellet Grain Size: 1

- Other indicators:: 1

We have InnoMag C-Series CCM products to apply to the industries of Plant Nutrition, Feed Additives, Pulp & Paper and Soil Remediation.

InnoMag®C - Caustic Calcined Magnesia Typical Chemical Value (Standard Grades) InnoMag C-Series MgO % CaO % SiO2 % Fe2O3 % Al2O3 % LOI % Grain size InnoMag C65 65 min 4.0 max 5.0 max 1.5 max 1.0 max 30 max InnoMag C73 73 min 4.0 max 5.0 max 1.5 max 1.0 max 15 max 60mesh

80mesh

200mesh

325mesh

0.3-0.8mm

0.3-1.5mm

0.3-0.2mm

0.2-1mmInnoMag C83 83 min 3.0 max 8.5 max 1.5 max 1.0 max 6.0 max InnoMag C85 85 min 3.0 max 8.5 max 1.5 max 1.0 max 6.0 max InnoMag C87 87 min 3.0 max 8.5 max 1.5 max 1.0 max 5.0 max InnoMag C90 90 min 2.5 max 5.0 max 1.0 max 1.0 max 3.0 max InnoMag C92 92 min 2.5 max 5.0 max 1.0 max 1.0 max 3.0 max *Grain size from <325 mesh to big lumps can be customized. -

20kg PP/PE bag.

25kg PP/PE bag.

50kg PP/PE bag.

Big PP bag with or without bottom spout, with or without PE liner.

Store product in a dry area, remaining sealed.

Shelf life is 12 months under good storage condition. -

Magnesia (MgO) is produced largely by the calcination of natural minerals (about 89%), principally magnesite (MgCO3), and rarely from brucite (Mg(OH)2), dolomite (CaMg(CO3)2) or hydromagnesite (4MgCO3•Mg(OH)2•4H2O). About 11% is produced synthetically by calcination of Mg(OH)2 derived as a precipitate from seawater and brines.

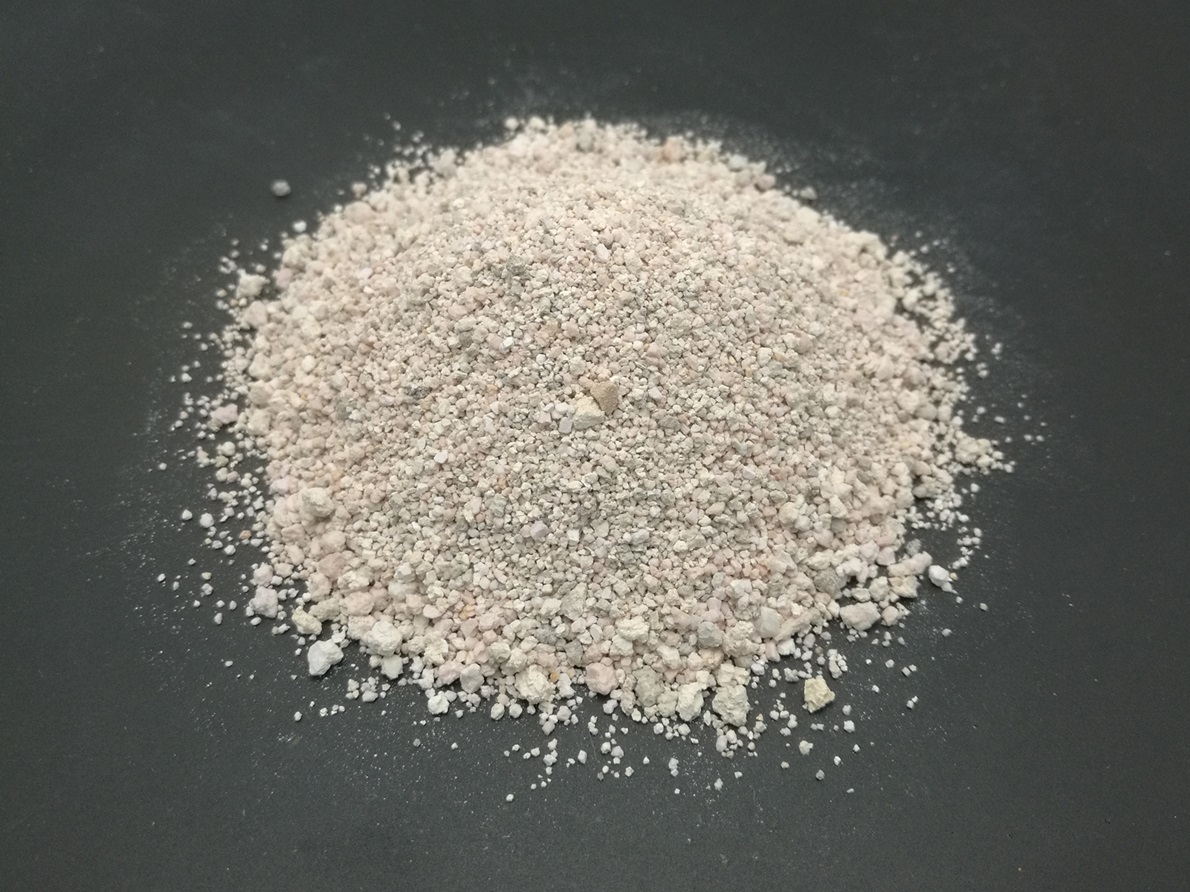

The most common method used for MgO production is the calcination of magnesite. In general, three types of MgO are produced from magnesite: caustic calcined magnesia (CCM, calcined at 700 - 1000 °C); dead burned magnesia (DBM, calcined at 1500 - 2000 °C); fused magnesia (calcined at 2800 - 3000 °C). The temperature of calcination influences the crystal size and reactivity of the MgO product. CCM has the highest reactivity and greatest specific surface area compared with DBM and FM.

Based on the customers' application need, IMC strictly selects the most suitable ore, and uses mature process and whole-process quality control to ensure that the products have excellent chemical indicators and physical properties.

IMC offers general grade CCM products with full range of MgO content (60% to 98%), suitable reactivity, and a variety of particle sizes for application in Plant Nutrition, Feed Additives, Pulp & paper and Soil remediation.

-

-

Main Properties MgO Content (typical) 65%-92%

- Main Uses & Advantages

- Packaging & Storage

- 概要位置

- 顶部大图

- 蓝色模块数据小图

-

- Commodity name: General CCM 60%-98%

- Mgo Content:: 1

- typ:: 1

- Appearance: : 1

- Powder/Granular/Pellet Grain Size: 1

- Other indicators:: 1

We have InnoMag C-Series CCM products to apply to the industries of Plant Nutrition, Feed Additives, Pulp & Paper and Soil Remediation.

InnoMag®C - Caustic Calcined Magnesia Typical Chemical Value (Standard Grades) InnoMag C-Series MgO % CaO % SiO2 % Fe2O3 % Al2O3 % LOI % Grain size InnoMag C65 65 min 4.0 max 5.0 max 1.5 max 1.0 max 30 max InnoMag C73 73 min 4.0 max 5.0 max 1.5 max 1.0 max 15 max 60mesh

80mesh

200mesh

325mesh

0.3-0.8mm

0.3-1.5mm

0.3-0.2mm

0.2-1mmInnoMag C83 83 min 3.0 max 8.5 max 1.5 max 1.0 max 6.0 max InnoMag C85 85 min 3.0 max 8.5 max 1.5 max 1.0 max 6.0 max InnoMag C87 87 min 3.0 max 8.5 max 1.5 max 1.0 max 5.0 max InnoMag C90 90 min 2.5 max 5.0 max 1.0 max 1.0 max 3.0 max InnoMag C92 92 min 2.5 max 5.0 max 1.0 max 1.0 max 3.0 max *Grain size from <325 mesh to big lumps can be customized. -

20kg PP/PE bag.

25kg PP/PE bag.

50kg PP/PE bag.

Big PP bag with or without bottom spout, with or without PE liner.

Store product in a dry area, remaining sealed.

Shelf life is 12 months under good storage condition. -

Magnesia (MgO) is produced largely by the calcination of natural minerals (about 89%), principally magnesite (MgCO3), and rarely from brucite (Mg(OH)2), dolomite (CaMg(CO3)2) or hydromagnesite (4MgCO3•Mg(OH)2•4H2O). About 11% is produced synthetically by calcination of Mg(OH)2 derived as a precipitate from seawater and brines.

The most common method used for MgO production is the calcination of magnesite. In general, three types of MgO are produced from magnesite: caustic calcined magnesia (CCM, calcined at 700 - 1000 °C); dead burned magnesia (DBM, calcined at 1500 - 2000 °C); fused magnesia (calcined at 2800 - 3000 °C). The temperature of calcination influences the crystal size and reactivity of the MgO product. CCM has the highest reactivity and greatest specific surface area compared with DBM and FM.

Based on the customers' application need, IMC strictly selects the most suitable ore, and uses mature process and whole-process quality control to ensure that the products have excellent chemical indicators and physical properties.

IMC offers general grade CCM products with full range of MgO content (60% to 98%), suitable reactivity, and a variety of particle sizes for application in Plant Nutrition, Feed Additives, Pulp & paper and Soil remediation.

-

-

Main Properties MgO Content (typical) 65%-92%

| Main Properties | ||

| MgO Content (typical) | 65%-92% |

Recommended Applications

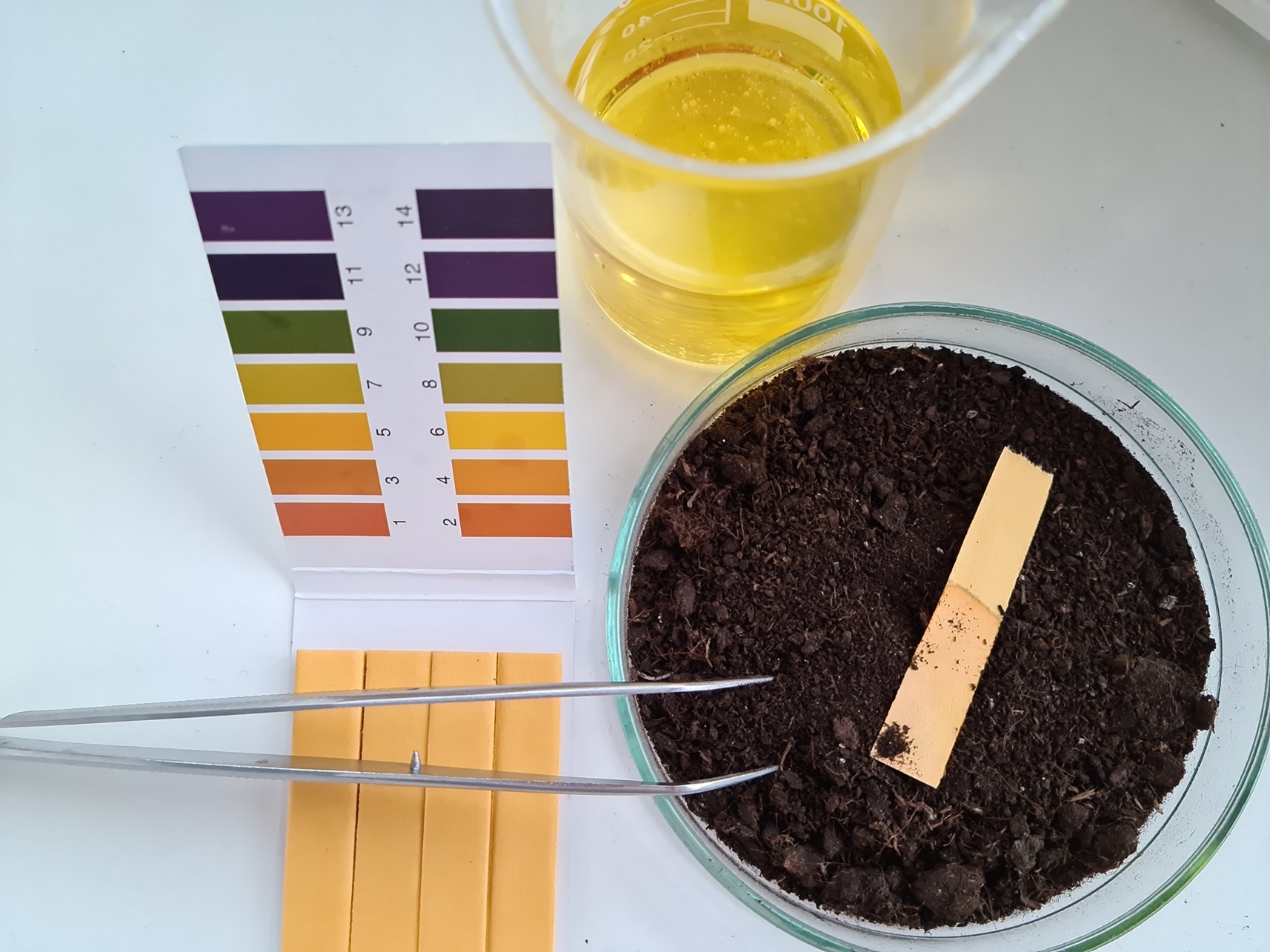

Magnesium is a macronutrient that is necessary to both plant growth and health. It is involved in several different processes, including photosynthesis, which nearly all living organisms are dependent on.

In recent more than decade, Magnesium Hydroxide, due to its divalent base alkali and moderate alkali properties, is increasingly used to replace caustic soda either partially or totally in Pulp & Paper industry.

Magnesium Oxide has been extensively investigated as effective immobilizing agent due to its excellent sorption affinities.

Magnesium (Mg) is a mineral that plays an essential role as cofactor of more than 300 enzymes. Mg is required in animal nutrition because of its major role in cellular metabolism and bone development and further to avoid adverse health conditions that impair animals' health and consequently their productivity.