SMC & BMC

SMC & BMC

A key requirement in the manufacture of Sheet Molding Compound (SMC) and Bulk Molding Compounds (BMC) is controlling the rheology throughout the production processes. The role of the thickening agent is to provide the required increase in viscosity of the resin paste mixture at a controlled rate during compounding, maturation (storage), and molding. Magnesium oxide (MgO) has been the most commonly used thickening agent for polyester based SMC/BMC. Magnesium oxide in the formulation can react with the free acid groups of the resin. This results after a few days in an enormous increase of the viscosity of the SMC/BMC formulation. A leather-like sheet is formed, which is almost non-sticky and easy to handle.

The correct selection of thickening agent is extremely important in producing stable and high-quality composite without forming defects and cracks.

Recommended Products

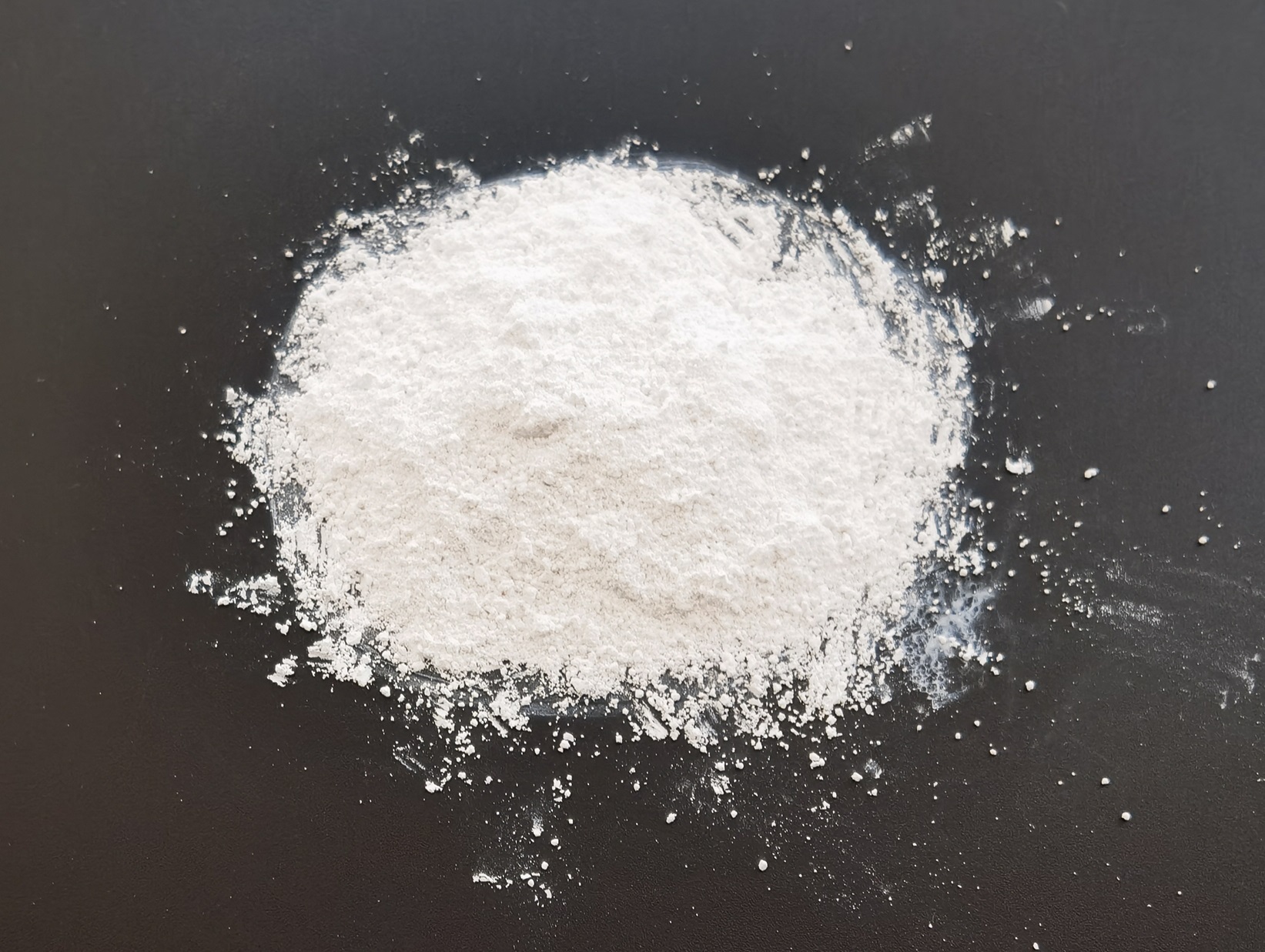

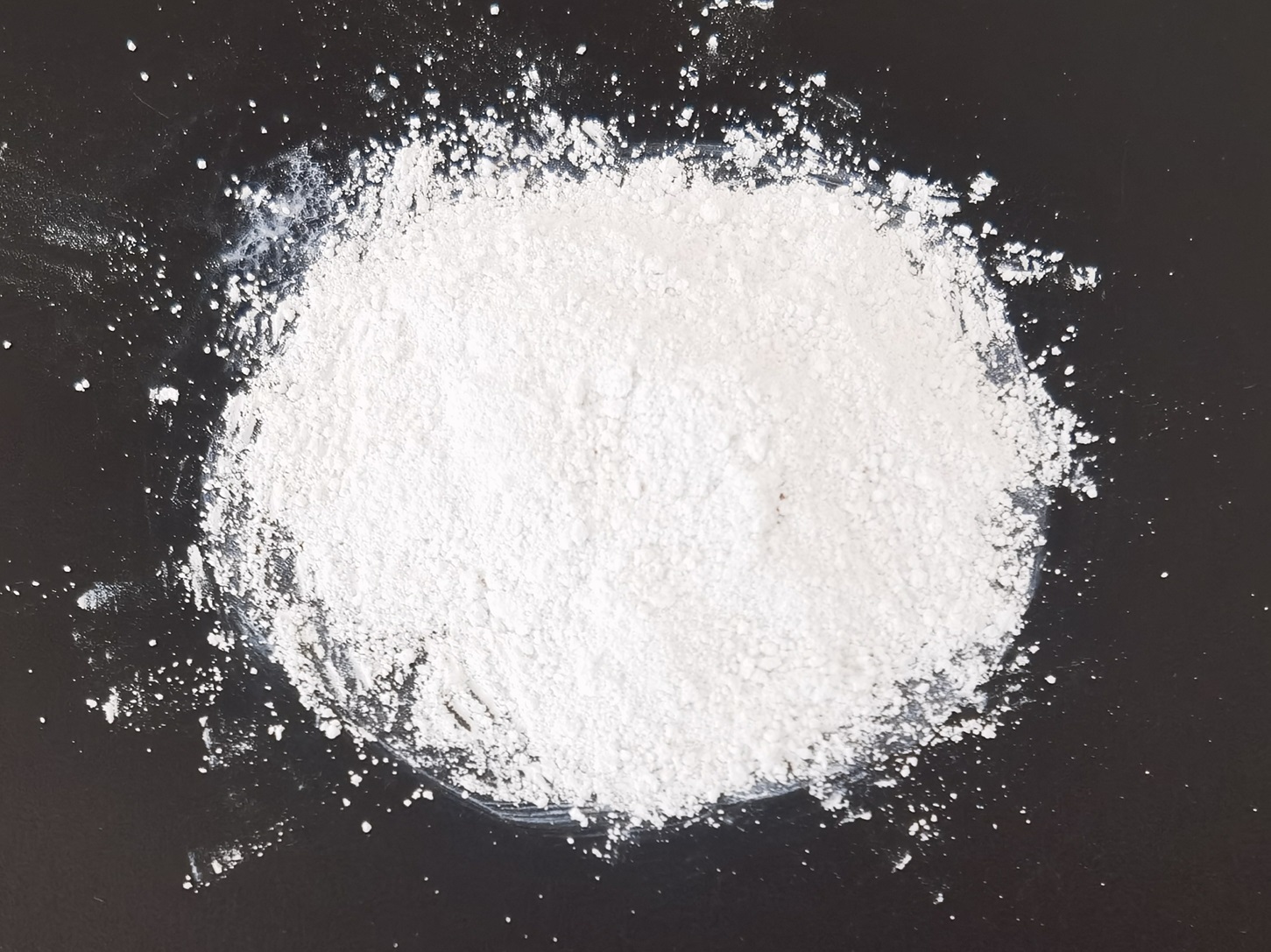

InnoMag150, derived from Salt Lake, is a white powder with high purity, high reactivity and large surface area.