MagPro

- Main Uses & Advantages

- Packaging & Storage

- 概要位置

- 顶部大图

- 蓝色模块数据小图

-

- Commodity name: MagPro

- Mgo Content:: 1

- typ:: 1

- Appearance: : 1

- Powder/Granular/Pellet Grain Size: 1

- Other indicators:: 1

Rubber & Plastic

The main applications of MagPro include the production of rubber compounds and rubber technical products based on halogenated rubbers, pneumatic tire parts, rubber cable sheathing and adhesives.

MagPro is used in rubber compounds as an acid scavenger, scorch controller, curing agent and heat stabilizer, acts as chelating agent for solvent-based rubber adhesives.

MagPro allows the processing of halogen-containing rubber compounds safely at high temperature, avoiding scorching and significantly increasing the productivity of the process.

MagPro enhances the strength of the adhesive joint in application of solvent-based rubber adhesives due to the formation of a chelate complex in reaction with phenol-formaldehyde resins added into the formulation.

SMC & BMC

MagPro can also be used in the production of SMC/BMC composites based on polyester and epoxy resins. The function of MagPro is as a thickening agent (chain extender).

-

20kg FFS PE bag (840 kg per pallet).

20kg FFS bag with 1 kg pre-weighted EVA low melt (75°C) bags (500 kg per pallet).

1 ton big-bag.

Store product in a dry area. Shelf life is 12 months. Bag must be kept re-sealed if the content was not used entirely. Exposure to moisture will reduce the activity significantly.

-

MagPro is a MgO brand owned by Brucite+. IMC has established a tight partnership with Brucite+ to sell MagPro products in Asia on behalf of Brucite+.

Brucite ore of the highest quality with a maximum content of magnesium hydroxide and a minimum amount of impurities is used for MagPro production.

MagPro has a high surface area of 130-170 m2/g and a median particle size D50 of 7-8 microns. Three grades are available: MagPro150, MagPro170 and MagPro150 XP. The right choice of the appropriate grade depends on the application, formulation and technology.

-

-

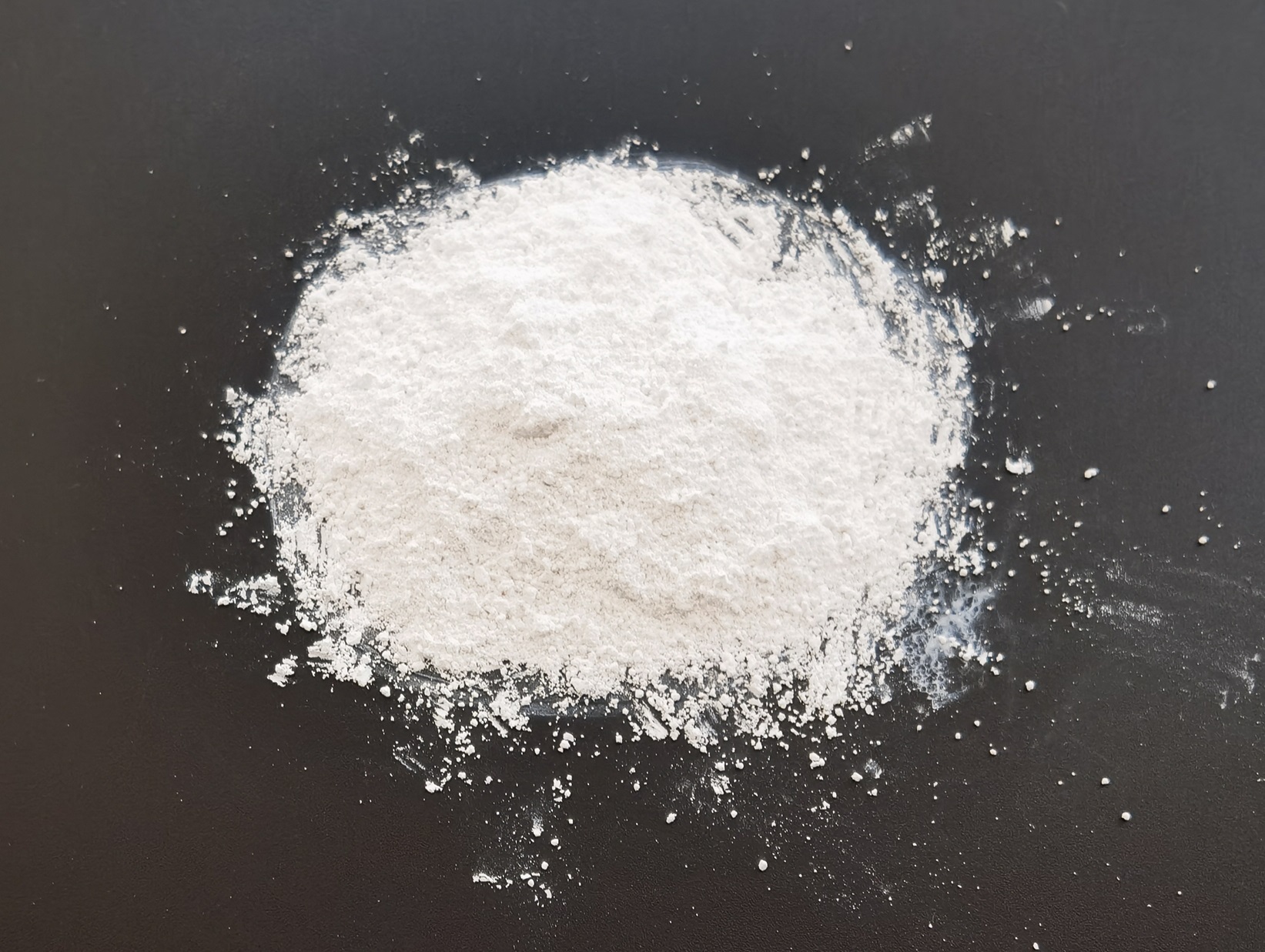

Main Properties Mgo Content (Ignited) 94%-96% Typical 95% Appearance White Powder Grain Size D50: 3.5 μm/7.5 μm SSA/BET Typ. 145 m2/g

- Main Uses & Advantages

- Packaging & Storage

- 概要位置

- 顶部大图

- 蓝色模块数据小图

-

- Commodity name: MagPro

- Mgo Content:: 1

- typ:: 1

- Appearance: : 1

- Powder/Granular/Pellet Grain Size: 1

- Other indicators:: 1

Rubber & Plastic

The main applications of MagPro include the production of rubber compounds and rubber technical products based on halogenated rubbers, pneumatic tire parts, rubber cable sheathing and adhesives.

MagPro is used in rubber compounds as an acid scavenger, scorch controller, curing agent and heat stabilizer, acts as chelating agent for solvent-based rubber adhesives.

MagPro allows the processing of halogen-containing rubber compounds safely at high temperature, avoiding scorching and significantly increasing the productivity of the process.

MagPro enhances the strength of the adhesive joint in application of solvent-based rubber adhesives due to the formation of a chelate complex in reaction with phenol-formaldehyde resins added into the formulation.

SMC & BMC

MagPro can also be used in the production of SMC/BMC composites based on polyester and epoxy resins. The function of MagPro is as a thickening agent (chain extender).

-

20kg FFS PE bag (840 kg per pallet).

20kg FFS bag with 1 kg pre-weighted EVA low melt (75°C) bags (500 kg per pallet).

1 ton big-bag.

Store product in a dry area. Shelf life is 12 months. Bag must be kept re-sealed if the content was not used entirely. Exposure to moisture will reduce the activity significantly.

-

MagPro is a MgO brand owned by Brucite+. IMC has established a tight partnership with Brucite+ to sell MagPro products in Asia on behalf of Brucite+.

Brucite ore of the highest quality with a maximum content of magnesium hydroxide and a minimum amount of impurities is used for MagPro production.

MagPro has a high surface area of 130-170 m2/g and a median particle size D50 of 7-8 microns. Three grades are available: MagPro150, MagPro170 and MagPro150 XP. The right choice of the appropriate grade depends on the application, formulation and technology.

-

-

Main Properties Mgo Content (Ignited) 94%-96% Typical 95% Appearance White Powder Grain Size D50: 3.5 μm/7.5 μm SSA/BET Typ. 145 m2/g

| Main Properties | ||

| Mgo Content (Ignited) | 94%-96% | |

| Typical | 95% | |

| Appearance | White Powder | |

| Grain Size | D50: 3.5 μm/7.5 μm | |

| SSA/BET | Typ. 145 m2/g | |

Recommended Applications

Magnesium Oxides (MgO) have been utilized in the Rubber Industry for more than 100 years. MgO is very important to many halogenated and nonhalogenated elastomers for numerous reasons.